Energy & Mass Transfer

ATC collaborates with leading manufacturers and research partners in the field of Mass and Energy Transfer Equipment, bringing extensive expertise to the chemical, power generation, biomass, paper, cement, mining, and water treatment industries.

The company supplies EPCs, OEMs, and process end-users with high-performance, engineered solutions designed to meet the most demanding process requirements.

Its comprehensive product portfolio includes heat exchangers, condensers, evaporators, vaporizers, and liquefaction systems, all engineered for extreme operating conditions such as cryogenic fluids, LNG, high-corrosion environments, high viscosity media, large-scale equipment, and high-temperature processes.

Used in: Supercritical CO2, SOFC, PEMFC, FSRU, FGSS, GNL, H2G, …

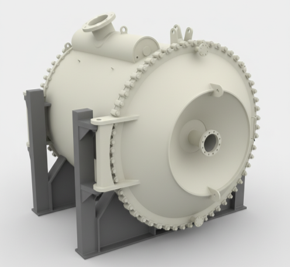

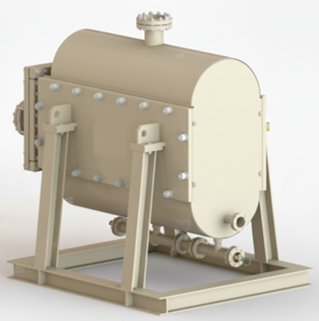

TEMA Exchangers

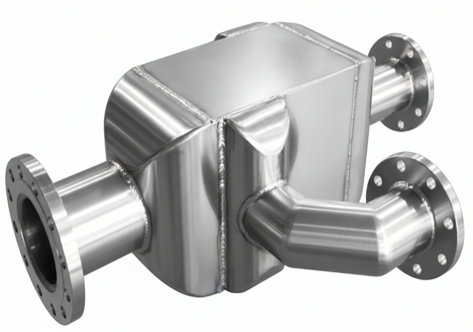

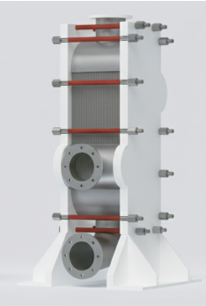

Brazed Plate Heat Exchanger

Brazed Plate Heat Exchanger uses stainless steel for both the plates and the brazing (vacuum brazing) to achieve superior corrosion resistance in aggressive media and at high temperatures, up to 400ºC. It is ideal for chemical, and other applications where the absence of ionic contamination are critical, despite its higher initial cost and slightly lower thermal efficiency

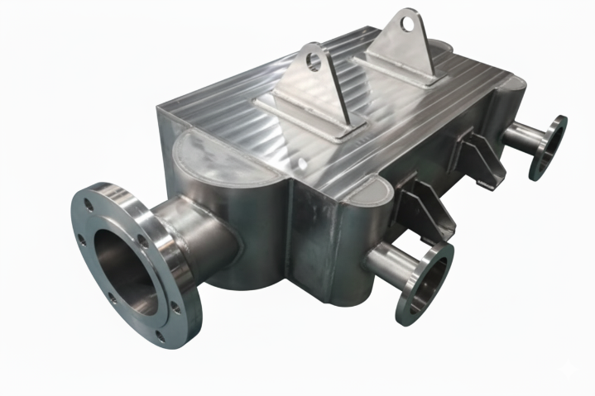

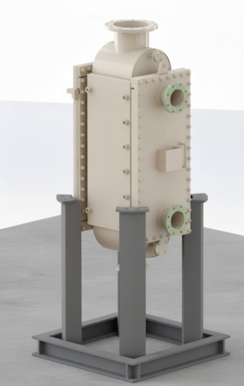

The Plate Block Heat Exchanger is a welded unit, constructed with plates that have no elastomeric gaskets, contained within a pressurized shell (or casing). Its robust design enables it to operate under extreme high-temperature and pressure conditions, and with corrosive fluids. It offers a high thermal power density in a reduced volume, optimizing efficiency. The elimination of gaskets minimizes maintenance requirements and the inherent risk of leaks, making it particularly effective in phase change applications. It is commonly manufactured from stainless steel alloys (304/316L) for chemical compatibility and durability.

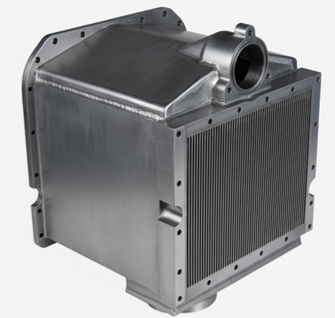

Intercooler

Intercooler is made of titanium alloy, giving it high strength, light weight, and strong resistance to seawater corrosion. It works in high-temperature, high-pressure conditions to transfer heat from hot gases to a cooling medium like seawater. The titanium alloy’s excellent thermal conductivity ensures efficient cooling and reliable performance.

In critical applications, Evaporators and Condensers are essential for regulating the temperature of both the cabin environment and sensitive electronic equipment. We provide advanced heat exchanger designs to ensure peak performance.

SPIRAL HEAT EXCHANGER: Perfect for heavy-duty heat exchange in highly contaminated and fouling processes. its self-cleaning design ensures exceptional operating time between maintenance and allows for fast, simple servicing.