WATER TREATMENTS FOR INDUSTRIAL PROCESSES

ATC offers extensive expertise in water treatment, providing complete skid-integrated solutions, from ATC facility in Spain or facility in India, also individual sales of main equipment, such as filtration, ultrafiltration, reverse osmosis, sludge treatment, evaporation, crystallization, chemical injection, gas injection, and many others, from international partners.

Through its international partnerships with technologically advanced manufacturers, ATC delivers comprehensive services that cover the entire process — from engineering and conceptual design to maintenance of process skids and manufactured equipment.

For industrial treatments, ATC focuses on optimizing the customer’s water loop, ensuring compliance with local regulations and promoting continuous improvement in operational efficiency.

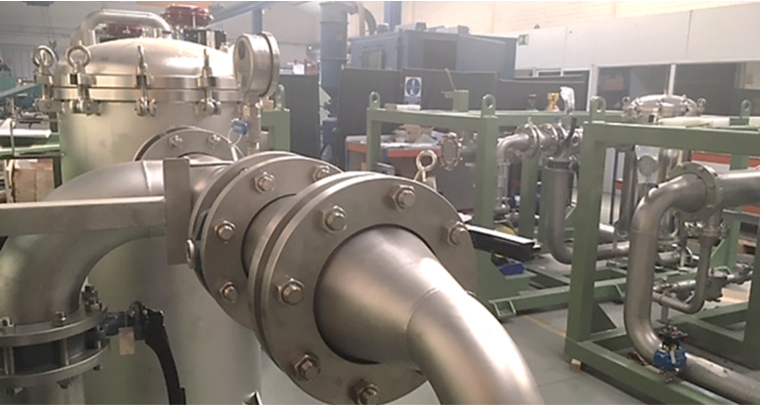

Water Treatement Skids

Filtration and Injection

Filtration and strainers can include ceramic filter elements, cellulose and textile elements, mesh screen or cartridges.

Extensive range of reverse osmosis systems for all water applications and budgets.

Chemical injection: Dosage of Phosphate; Hypochlorite; Bio-dispersant, Biocide…

Horizontal screw Decanter

The horizontal screw decanter centrifuge is a widely used piece of equipment for solid-liquid separation at an industrial level.

Depending on the characteristics of the material and the specific industry, it can be classified into decanters for dewatering, separation, or clarification. Additionally, with centripetal pump technology, it enables three-phase separation of two liquids and solids, or two liquid phases.

It can continuously separate more than 50% (by volume) of solids present in a liquid. Typical applications include the treatment of crude oil tank bottoms, waste oils, wastewater, sludge, fish meal, cleaning of used vegetable oils, paint sludge, among others.

Experts removing from Water the following elements

-Sodium Sulfate

-Leachate

-Nickel Plating

-Copper Foil

-Copper Sulfate

-Lithium

-Pesticide

-Chromium

-Chromate

-Bio Fermentation

-Washing Emulsion

Treatment form Wastewater from

-Landfill

-RO Reject concentrated

-MVR/multi-effect Mother

-Coating, Printing & Dyeing

-Grinding and Polishing

-Drawing Lubricating

-Electroplating

-Emulsion for Cutting

-Die Casting

-Chemicals

-Coal Chemical

THERMAL EVAPORATION

The pump evaporator uses heat pump energy to separate water from pollutants at about 35 °C, producing clear distilled water and reducing by up to 99%. It operates automatically without supervision and converts wastewater into highly concentrated liquid. This process minimizes hazardous waste volume and significantly lowers treatment costs. It is widely applied in steel, metal, casting, aluminum, galvanizing, chemical, and emulsion industries.

THERMAL CRYSTALLIZER

The thermal evaporation crystallizer uses steam to evaporate wastewater at 35 °C under negative pressure, producing clear distillate and minimal solid waste. It operates fully automatically, 24/7, as a true zero-liquid-discharge solution. A special scraper prevents scaling by cleaning the tank walls and mixing the wastewater. This improves evaporation efficiency and makes it suitable for new energy, RO reject, concentrate and chemical industries.

HEAT PUMP EVAPORATOR

The low-temperature vacuum crystallizer with heat pump operates solely on electricity, without steam or cooling water. Evaporation occurs at 35 °C under negative pressure, while a scraper prevents crystal adhesion on the tank walls. It converts wastewater into dry solid crystals and clear distillate, with automatic discharge. It is used in industrial solutions, minimizing solid or semi-solid waste.